Facilities

T5 Reflected Shock Tunnel

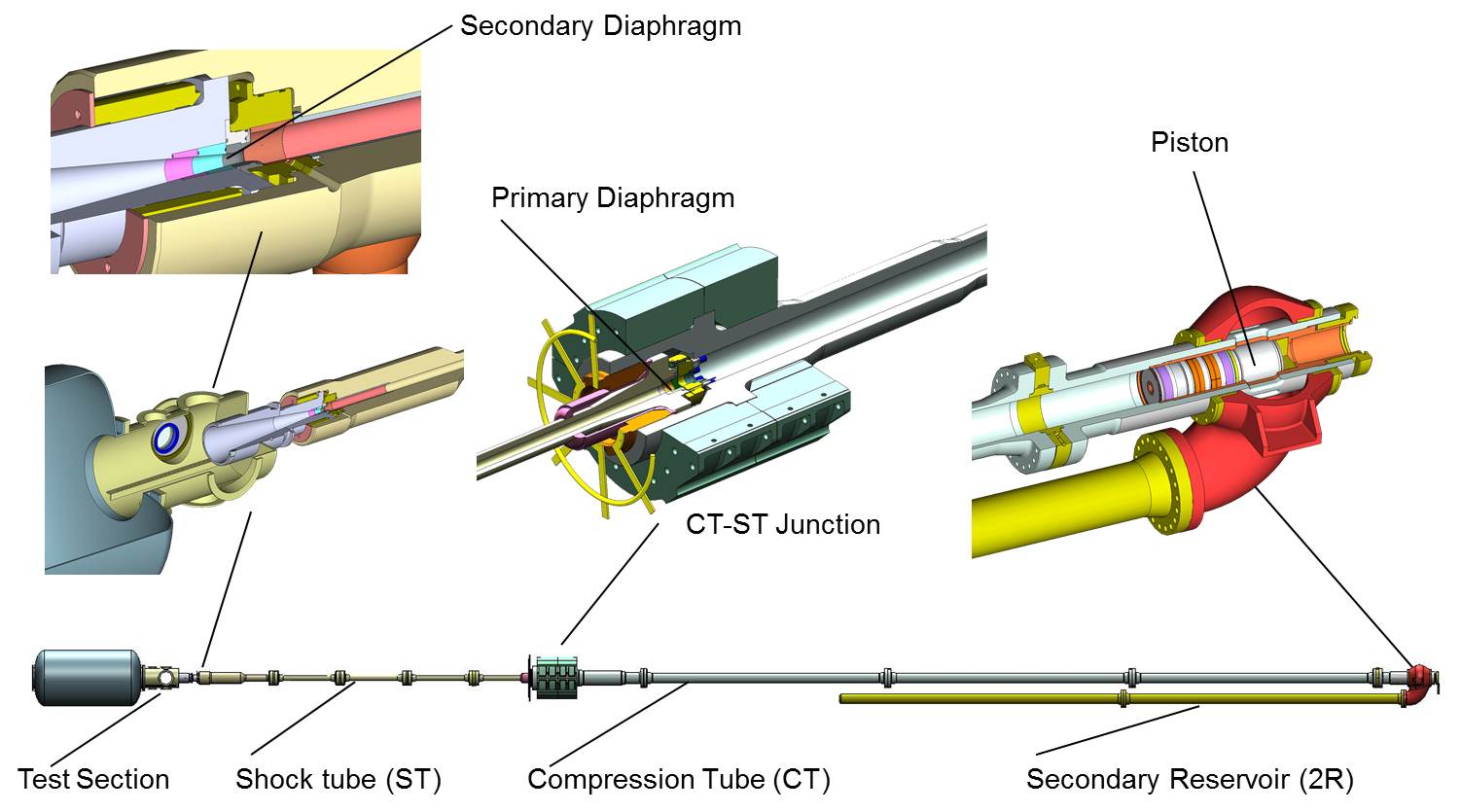

The T5 facility at GALCIT is a free piston shock tunnel, and is named T5 because it is the fifth in a series of shock tunnels built by or under the supervision of R. J. Stalker, H. G. Hornung, and colleagues (the previous four are in Australia). The facility is capable of producing flows of air or nitrogen up to specific reservoir enthalpy of 25 MJ/kg, reservoir pressure of 100 MPa, and reservoir temperature 10000 K. It achieves this by using a free piston to adiabatically compress the driver gas of the shock tunnel to very high pressure, as high as 130 MPa. A schematic of the facility is shown below.

A test starts with the 120 kg piston loaded into the launch manifold between the secondary reservoir (2R) and the compression tube (CT). The 2R is filled with compressed air (typically at 8 MPa, but sometimes as high as 15 MPa) used to drive the piston, and the CT (30 m long and 0.3 m in diameter) is filled with the driver gas, a mixture of helium and argon. The piston is held in place by evacuating the space behind it. A stainless steel diaphragm (typically 7 mm thick) separates the CT from the shock tube (ST). The ST (12 m long and 0.09 m in diameter) is filled with the test gas. A thin mylar diaphragm just downstream of the nozzle throat isolates the test gas from the test section and dump tank (not shown in the figure), which are both evacuated before a test.

The facility is fired by opening a valve to let high pressure air into the space behind the piston. Then the piston moves forward, uncovering large slots open to the high pressure air in the 2R. The piston can reach maximum speeds in excess of 300 m/s, and it is the resulting momentum which compresses the driver gas to a pressure much higher than the initial pressure in the 2R. The CT, ST, and nozzle are attached together as one unit, free to move horizontally and recoil with the shift in center of mass due to the piston motion. An inertial mass of 14 tons at the CT-ST junction greatly reduces this recoil, but the facility still moves about 10 cm during a test. The test section and dump tank remain stationary while the nozzle noves in a sliding seal.

When the primary diaphragm bursts, a shock wave propagates into the ST with a speed that can range from 2 to 5 km/s. The incident shock reflects off the end wall, breaking the secondary diaphragm and forming a stationary region of test gas at high temperature and pressure in the reservoir of the nozzle. The contoured nozzle has an exit diameter of 31.4 cm and an interchangeable throat, but it is designed to operate at Mach 5.2 with high temperature air and a 30 mm diameter nozzle throat. The free stream conditions at the nozzle exit are typically on the order of 30 kPa pressure and 2000 K temperature. The useful test time, before any significant loss of reservoir pressure, is typically about 1 ms.

A more detailed description of the T5 facility and its performance envelope can be found in H. G. Hornung's paper "Performance data of the new free-piston shock tunnel at GALCIT" (AIAA 92-3943).